At the current stage of design, claytronics hardware operates from macroscale designs with devices that are much larger than the tiny modular robots that set the goals of this engineering research. Such devices are designed to test concepts for sub-millimeter scale modules and to elucidate crucial effects of the physical and electrical forces that affect nanoscale robots.

> Planar catoms test the concept of motion without moving parts and the design of force effectors that create cooperative motion within ensembles of modular robots.

> Electrostatic latches model a new system of binding and releasing the connection between modular robots, a connection that creates motion and transfers power and data while employing a small factor of a powerful force.

> Stochastic Catoms integrate random motion with global objectives communicated in simple computer language to form predetermined patterns, using a natural force to actuate a simple device, one that cooperates with other small helium catoms to fulfill a set of unique instructions.

> Giant Helium Catoms provide a larger-than-life, lighter-than-air platform to explore the relation of forces when electrostatics has a greater effect than gravity on a robotic device, an effect simulated with a modular robot designed for self-construction of macro-scale structures.

> Cubes employ electrostatic latches to demonstrate the functionality of a device that could be used in a system of lattice-style self-assembly at both the macro and nano-scale.

Each section devoted to an individual hardware project provides an overview of the basic functionality of the device and its relationship to the study of claytronics. As these creative systems have evolved in the Carnegie Mellon-Intel Claytronics Hardware Lab, they have prepared the path for development of a millimeter scale module that will represent the creation of a self-actuating catom - a device that can compute, move, and communicate - at the nano-scale.

2.1.1 Millimetre Scale Catoms -

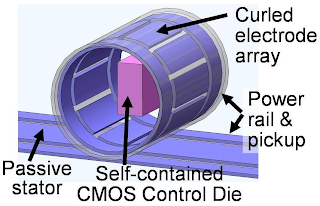

Realizing high-resolution applications that Claytronics offers requires catoms that are in the order of millimetres. In this work, we propose millimetre-scale catoms that are electrostatically actuated and self-contained. As a simplified approach we are trying to build cylindrical catoms instead of spheres.

The millimetre scale catom consists of a tube and a High voltage CMOS die attached inside the tube. The tubes are fabricated as double-layer planar structures in 2D using standard photolithography. The difference in thermal stress created in the layers during the fabrication processes causes the 2D structures to bend into a 3D tubes upon release from the substrate. The tubes have electrodes for power transfer and actuation on the perimeter.

The high voltage CMOS die is fabricated separately and is manually wire bonded to the tube before release. The chip includes an AC-DC converter, a storage capacitor, a simple logic unit, and output buffers.

The catom moves on a power grid (the stator) that contains rails which carry high voltage AC signals. Through capacitive coupling, an AC signal is generated on the coupling electrodes of the tube, which is then converted to DC power by the chip. The powered chip then generates voltage on the actuation electrodes sequentially, creating electric fields that push the tube forward.

1.1.2 Cubes

A lattice-style modular robot, the 22-cubic-centimeter Cube, which has been developed in the Carnegie Mellon-Intel Claytronics Research Program, provides a base of actuation for the electrostatic latch that has also been engineered as part of this program. The Cube (pictured below, right) also models the primary building block in a hypothetical system for robotic self-assembly that could be used for modular construction and employ Cubes that are larger or smaller in scale than the pictured device.

The design of a cube, which resembles a box with starbursts flowering from six sides, emphasizes several performance criteria: accurate and fast engagement, facile release and firm, strong adhesion while Cube latches clasps one module to another. Its geometry enables reliable coupling of modules, a strong binding electrostatic force and close spacing of modules within an ensemble to create structural stability.

Designed to project angular motion from the faces of its box-like shape, the Cube extends and contracts six electrostatic latching devices on stem assemblies. By this mechanism, the latches of a Cube integrate with latches on adjacent Cubes for construction of larger shapes.

With extension and retraction of stem-drive arms that carry the latches, the module achieves motion, exchanges power and communicates with other Cubes in a matrix that contains many of these devices. Combining these forces of motion, attachment and data coupling, Cubes demonstrate a potential to create intricate forms from meta-modules or ensembles that consist of much greater numbers of Cubes; numbers determined by the scale of Cubes employed in an ensemble of self-construction.

To create motion for a Cube in a matrix of many cubes, a direct-current motor inside the Cube's central frame actuates expansion and contraction of electrostatic latches fixed to the ends of independent worm-drive assemblies. Housed in individual tubes, the assemblies provide arms to support the motion of latches from six sides of the central frame. Linear motion enables the Cube to exploit considerable lateral flexibility for forming shapes within a matrix. The Cube measures 22 cm between faces when fully contracted and 44 cm when fully expanded.

The worm-drive assembly extends the face of one cube to create contact with the face of an adjacent cube. The electrodes on each face create one-half of a capacitor. When the two "genderless," star-shaped faces of adjacent Cubes integrate their combs, they complete a capacitor and form an electrostatic couple from the contact of electrodes, which binds the faces as a completed latch.

The capacitive couple, which forms the electrostatic latch, provides within an ensemble of Cubes not only adhesion and structural stability but also the transmission of power and communication. In a meta-module of many cubes, power would move in discrete packets rather than as a continuous current, in a mode similar to data moving through a network in discrete packets of bytes that reassemble into larger packages of information at the point of delivery. This packet delivery of energy would enable the meta-module or ensemble to move power from cubes that have a surplus to others that require more of it.

Cubes reconfigure by expanding the connected faces of two neighbouring modules so that one is pushed one block length across the assembly. Then by contracting its extended arm, it pulls the next module forward. Such motion within a meta-module consisting of sufficiently large numbers of cubes could form any conceivable shape.

This micro-electro-mechanical device thus presents a model for a type of robotic self-assembly of complex structures at both macro and micro scales.

1.1.3 Powering Catoms with Magnetic Resonant Coupling

As a potential means for providing power to catoms without using electrical connections, they have experimentally demonstrated wireless power transfer via magnetic resonant coupling is in a system with a large source coil and either one or two small receivers. Resonance between source and load coils is achieved with lumped capacitors terminating the coils.

They have developed a circuit model to describe the system with a single receiver, and extended it to describe the system with two receivers. With parameter values chosen to obtain good fits, the circuit models yield transfer frequency responses that are in good agreement with experimental measurements over a range of frequencies that span the resonance. Resonant frequency splitting is observed experimentally and described theoretically for the multiple receiver system.

In the single receiver system at resonance, more than 50% of the power that is supplied by the actual source is delivered to the load. In a multiple receiver system, a means for tracking frequency shifts and continuously retuning the lumped capacitances that terminate each receiver coil so as to maximize efficiency is a key issue for future work.

In the single receiver system at resonance, more than 50% of the power that is supplied by the actual source is delivered to the load. In a multiple receiver system, a means for tracking frequency shifts and continuously retuning the lumped capacitances that terminate each receiver coil so as to maximize efficiency is a key issue for future work.

1.1.4 Planar Catoms

The self-actuating, cylinder-shaped planar catom tests concepts of motion, power distribution, data transfer and communication that will be eventually incorporated into ensembles of nano-scale robots. It provides a testbed for the architecture of micro-electro-mechanical systems for self-actuation in modular robotic devices. Employing magnetic force to generate motion, its operations as a research instrument build a bridge to a scale of engineering that will make it possible to manufacture self-actuating nano-system devices.

The planar catom is approximately 45 times larger in diameter than the millimetre scale catom for which its work is a bigger-than-life prototype. It operates on a two-dimensional plane in small groups of two to seven modules in order to allow researchers to understand how micro-electro-mechanical devices can move and communicate at a scale that humans cannot yet readily perceive -- or imagine. It forms a bridge into this realm across the evolving design of a sophisticated electro-magnetic system whose features have followed a path of trail and error as the CMU-Intel Claytronics Research Team has tested the concept of a robot that moves without moving parts.

In its brief history of demonstrating motion without moving parts, the planar catom has evolved through eight versions. It began life as a concept vehicle engineered with catalog-sourced hardware. It has become a custom-designed electronic and magnetic system that carries a complete control package aboard its module.

Weighing 100 grams, Planar Catom V8, shown in the picture here, presents for view its stack of control and magnet-sensor rings. Its solid state electronic controls ride at the top of the stack. An individual control ring is dedicated to each of the two rings of magnet sensors, which ride at the base of the module. Two thin threaded rods extend like lateral girders from top to bottom through the outside edge to brace the rings. A central connector stack carries circuits between control and magnet rings, enabling easier handling and maintenance of components while also providing internal alignment and stability along the cylinder's axis.

At the base of the planar catom, the two heavier electro-magnet rings, which comprise the motor for the device, also add stability. To create motion, the magnet rings exchange the attraction and repulsion of electromagnetic force with magnet rings on adjacent catoms. From this conversion of electrical to kinetic energy, the module achieves a turning motion to model the spherical rotation of millimeter-scale catoms.

Pictured in a top view (left, below), two magnet rings from Planar Catom V7 display the arrangement of their 12 magnets around individual driver boards and the coil design for horseshoe magnets introduced with Version 6 and then upgraded in versions 7 and 8.

The magnets are arranged in the containment ring as the straightedge faces of a 12-sided polygon seated in the acrylic plate that holds them in place. The horseshoe magnets feature 39AWG magnet wire wrapped around AISI 1010 steel cores, components selected to balance machinable metal and flux-saturation density.

Replacing barrel-shaped, round-face magnets in Planar Catom Versions 1-5, the horseshoe magnet was adopted to boost magnet strength and create a wider footprint. It also represents an evolution of the use of flat-surface magnets, which were introduced in Planar Catom Version 5. Flat surfaces prove to be more efficient for contact than round-face magnets.

Economy in the design of the controls also makes more room for the rest of the robust package of electronics that operate the module. The picture to the right displays a planar catom controller ring with light emitting diodes (LEDs) arranged around its perimeter. This board directs the two magnet driver boards embedded in the magnet rings, as shown in the image above.

The custom design of the electronics achieves a very high level of capacity to guide the module's performance. Built with the smallest components commercially available, each controller board contains 5 layers of embedded microcircuits on 45 mm diameter acrylic boards. At this density of circuit design, each of the two controller rings provides approximately 40 times the embedded instrumentation of a standard robotics controller package in 2/5th the space. The resulting capacity of its boards enables the module to carry on board all devices needed to manage its firmware, drivers and 24 magnets.

A more typical robotics servo controller would carry a microprocessor, motors, servos and other devices on one side of a 50 mm x 75 mm board embedded with two layers of microcircuits. While building planar catoms to investigate a customized actuation system that creates motion without moving parts, the design team also achieved the complementary objective of constructing a robust, self-contained modular robot.

Another component of this robust electronic system is shown in the picture below of a Planar Catom Infrared Communication Board. On this device, the Infrared Data (IrDA) transmitters and receivers are separately multiplexed to transmit and receive signals on separate channels, allowing fast, simultaneous transmission on all channels. These global communication features anticipate the necessity of debugging and reprogramming large ensembles of catoms.

Another component of this robust electronic system is shown in the picture below of a Planar Catom Infrared Communication Board. On this device, the Infrared Data (IrDA) transmitters and receivers are separately multiplexed to transmit and receive signals on separate channels, allowing fast, simultaneous transmission on all channels. These global communication features anticipate the necessity of debugging and reprogramming large ensembles of catoms.

The engineering goal for these components is a system that supports cooperative behaviour among nanoscale robotic modules. This concept of machine behaviour is one in which the primary devices direct their own motion toward a common goal by employing functionality that focuses every element of design on the requirements of the ensemble rather than on those of the individual robot. The engineering design thus adheres to the ensemble axiom by incorporating in these devices only those functions that advance the functionality of the ensemble.

2.1.5 Electrostatic Latches

A simple and robust inter-module latch is possibly the most important component of a modular robotic system. The electrostatic latch pictured below was developed as part of the Carnegie Mellon-Intel Claytronics Research Project. It incorporates many innovative features into a simple, robust device for attaching adjacent modules to each other in a lattice-style robotic system. These features include a parallel plate capacitor constructed from flexible electrodes of aluminium foil and dielectric film to create an adhesion force from electrostatic pressure. Its physical alignment of electrodes also enables the latch to engage a mechanical shear force that strengthens  its holding force.

its holding force.

its holding force.

its holding force.

The electrodes that form the latch fit into "genderless" faces constructed as star-shaped plastic frames carried by each module. In the design of the circuits, each electrode functions as one-half of a complete capacitor. A latch forms when the faces of two adjacent modules come together and create an electrostatic field between the flexible electrodes.

Each star-shaped face supports passive self-alignment of the link with a 45-degree blade angle at the top of each comb on the face. The design also supports easy disengagement with a five-degree release angle along the vertical lines of the faces.

The parallel alignment of the electrodes in forming the complete capacitor plate introduces a shear force - or friction - that strengthens the binding of the latch. Once formed, the latch requires almost zero static power to maintain its holding force. Additionally, the presence of multiple circuits among the electrodes provides the latch with simultaneous capacity also to exchange power and communicate data between modules. These features make the device suitable for lattice-style robots in both nanotechnology (micro-scale) and macroscale applications.

In its electrical design, the electrostatic latch uses the closely spaced plates of a parallel capacitor, which generate an electrostatic force to attract each other when the capacitor is charged. After the latch closes, residual charge maintains the latch indefinitely. A thin dielectric film on each conductive plate provides insulation.

Employing capacitive coupling, the latch adheres with a force of 0.6 N/cm2 while requiring almost zero static power to maintain the force after the latch forms. A specific degree of flexibility in the electrodes maximizes the mutual coupling of electrodes. Electrodes that are too rigid or too flexible do not provide an adequate level of latch performance.

Moreover, the electrodes create multiple circuits, which allow transmission of power and data for communication between modules. This design serves several functions within the robotic module and enables a level of efficiency that reduces requirements for total weight, volume and complexity. This design feature thus yields simpler paths to performance and scaling goals in robotic modules.

The factor that enables electrostatic adhesion to be effective at the macroscale is an interface for the electric field that also creates a shear force from mechanical friction. A combination of electrostatic and shear forces results from the alignment. Currently, the electrostatic latch is being tested on a modular Cube that is 28 cm on a side.

2.1.6 Stochastic Catoms

A concept being tested in the Carnegie Mellon-Intel Claytronics Research Project is the use of stochastic reconfiguration in ensembles of modular robots. In this mode of reconfiguration, the module relies on random motion and follows unmapped paths to gain in the ensemble a position where it can determine its exact location and contribute its form to the overall structure.

Depending upon the scale of the device, actuation of the module's motion can be created with various sources of energy, including currents of air, electrostatics or, in the case of a study of the phenomenon during Andrew's Leap, Carnegie Mellon's summer enrichment program, the propelling motion of high school students throwing helium-filled balloons.

From such forces, a module derives an initially incoherent motion that causes random contacts with other modules. In these contacts, the module evaluates the appropriateness of forming a connection with the other module. The module makes its decision by evaluating the relation of its form in the instance of the contact location to the ensemble's overall goal for a predetermined shape. Based on this evaluation, the module either forms a bond or continues in motion.

To demonstrate the applicability of stochastic reconfiguration to modular robots, the Andrew's Leap students constructed an ensemble of Mylar balloons in the shape of cubes, each approximately 1/2 meter on a side. They also created a lightweight electronic module to support each catom's functionality as well as simple latches for the faces of each cube to provide a means of data exchange and attachment among catoms. To create buoyancy, each catom was filled with helium.

To demonstrate the applicability of stochastic reconfiguration to modular robots, the Andrew's Leap students constructed an ensemble of Mylar balloons in the shape of cubes, each approximately 1/2 meter on a side. They also created a lightweight electronic module to support each catom's functionality as well as simple latches for the faces of each cube to provide a means of data exchange and attachment among catoms. To create buoyancy, each catom was filled with helium.

Computations within the electronic module follow a simple program, known as a graph grammar, which enables each stochastic catom independently to determine its location in relation to other catoms in the ensemble - and in relation to a predetermined shape into which the catoms locate their positions from random motion

Localizing its position while in contact with other catoms, a catom either engages its electrostatic latch in order to bind to an adjacent robot or signals for separation and further stochastic motion until it identifies a location where it will contribute to the desired global shape.

As a type of swarm behavior conceived for nano-scale robots, stochastic motion among catoms would draw upon mathematical probability whose effective potential to shape forms would increase with greater numbers of smaller-scale modules.

2.1.7 Giant Helium Catoms

A Giant Helium Catom (GHC) measures eight cubic meters when its light Mylar skin fills with helium to acquire a lifting force of approximately 5.6 kilograms. This lift is necessary to elevate a frame of carbon fiber rods and plastic joints, which contains the balloon and carries electronic sensors and a communication package to actuate the catom's motion and engage it with other GHCs. The roughly square balloon is constructed with edge dimensions of approximately 1.9 meters from 4 meter x 1 meter sheets of Mylar. Each balloon uses four sheets of this material.

The Giant Helium Catom provides researchers a macroscale instrument to investigate physical forces that affect microscale devices. The GHC was designed to approximate the relationship between a near-zero-mass (or weightless) particle and the force of electro-magnetic fields spread across the surface of such particles. Such studies are needed to understand the influence of surface tensions on the engineering of interfaces for nanoscale devices.

In addition to its role as a test-bed for nanoscale surface tensions, the great helium catom also offers a prototype design for a low-mass system of robotic self-assembly that can be used at life-scale in solar system travel. Because of its very low mass, it was conceived also as a macroscale construction system for delivery by space craft. Such a system would deploy dwellings and workstations on the Moon and the planet Mars in advance of astronauts who would occupy the pre-constructed stations for long-term exploration and interplanetary travel.

In addition to its role as a test-bed for nanoscale surface tensions, the great helium catom also offers a prototype design for a low-mass system of robotic self-assembly that can be used at life-scale in solar system travel. Because of its very low mass, it was conceived also as a macroscale construction system for delivery by space craft. Such a system would deploy dwellings and workstations on the Moon and the planet Mars in advance of astronauts who would occupy the pre-constructed stations for long-term exploration and interplanetary travel.

On each face, the GHC cube carries a novel electrostatic latching system that enables the device to move across the faces of other catoms and to communicate with them. The design for this latch system centres on a thin aluminium foil flap across each of the 12 edges of the Mylar cube. This is essentially a square that crosses each of the catom's edges on a diagonal in order to create two triangular flaps lying at a right angle to each other against the two adjacent surfaces of the catom. With this arrangement, each surface of the catom has four triangular flaps with peaks pointed toward the centre of the face.

Among the six faces, the triangular flaps provide each catom with the means to form an electrostatic latch with another cube from 24 positions - providing the cubes with a capacity to move at right angles in any direction. In addition to motion, the latches also equip the GHC with the means to communicate across the ensemble of catoms. In the drawing below, one Giant Helium Catom pivots across the surface of another, revealing the positions and attachments of triangular electrostatic flaps.

Among the six faces, the triangular flaps provide each catom with the means to form an electrostatic latch with another cube from 24 positions - providing the cubes with a capacity to move at right angles in any direction. In addition to motion, the latches also equip the GHC with the means to communicate across the ensemble of catoms. In the drawing below, one Giant Helium Catom pivots across the surface of another, revealing the positions and attachments of triangular electrostatic flaps.

Two electrodes on each flap create the electrostatic forces that enable latches to form a capacitive couple between flaps on adjacent GHCs. A dielectric material (Mylar) isolates the pair of electrodes (and electrical charges from them) on each flap to prevent their direct electrical contact. This design enables voltage differences applied to the electrodes to accumulate charges, create electrostatic force on the flap and align with electrodes that carry an opposing charge on the flap of an adjacent GHC.

Each flap moves independently with the assistance of a spring-loaded mechanism and a composite shape-memory alloy (SMA). GHCs deliver power to each other using capacitive coupling with alternating current (AC). The AC power generated at the neighbouring catom is rectified and regulated, and the resulting DC power is used for processing and other electronics on the module. A high-voltage generator creates the electrostatic force to activate the latches.

Although the project planned to construct six giant helium catoms to simulate an ensemble, in its 3-month duration, this experiment tested this interface on two catoms. Experience with this design provided the Carnegie Mellon-Intel Claytronics Research Project with substantial experience in the design characteristics of micro-electro-mechanical latches.

No comments:

Post a Comment